Stone washing, also known as stone washing or acid washing, is a textile finishing technique that has revolutionized the denim industry. This unique process involves washing denim garments with abrasive stones or chemicals to achieve a soft, worn-in appearance, creating a vintage aesthetic that has captivated fashion enthusiasts for decades. In this article, we’ll explore the art of stone washing and its impact on the world of denim.

The Origins of Stone Washing

The origins of stone washing can be traced back to the 1970s, a time when denim jeans were gaining popularity as a symbol of rebellion and counterculture. Denim manufacturers sought to replicate the natural fading and distressing that occurs with regular wear, leading to the development of the stone washing technique. By washing denim garments with abrasive stones, such as pumice or volcanic rocks, they were able to achieve the desired worn-in look, giving birth to the trend of stone washed jeans.

The Stone Washing Process

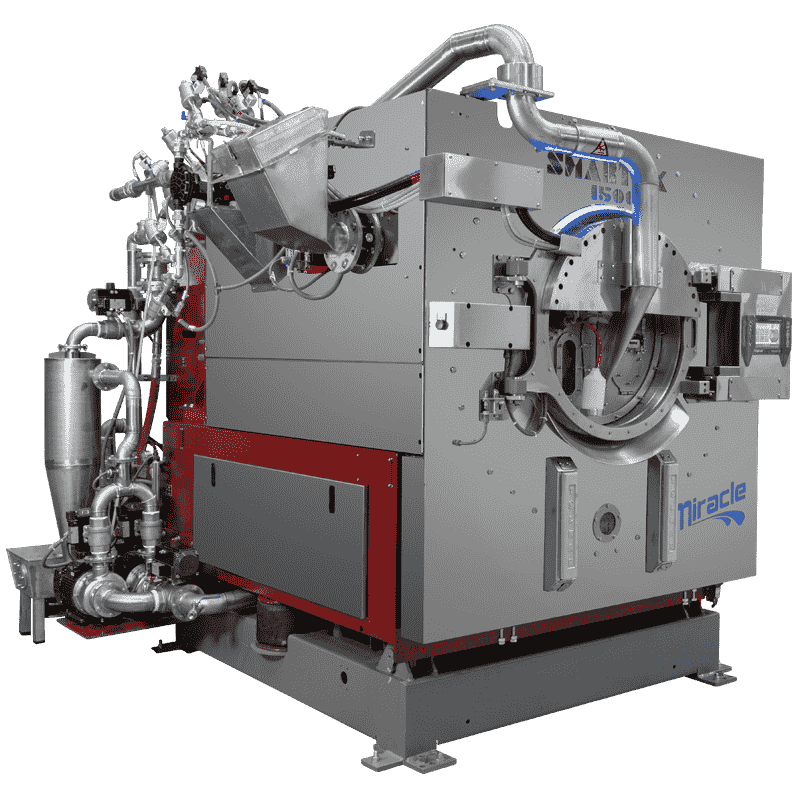

The stone washing process begins with pre-soaking denim garments to remove any dirt or impurities. Next, the garments are placed in a large industrial washing machine along with abrasive stones and special chemical additives. As the machine agitates the stones against the fabric, friction and abrasion occur, softening the fibers and creating a worn-out appearance. Depending on the desired effect, the duration and intensity of the washing cycle may vary, with some garments undergoing multiple wash cycles to achieve the desired level of distressing.

The Appeal of Stone Washed Denim

Tolkar Stone washed denim offers a unique blend of style and comfort that appeals to a wide range of consumers. The soft, lived-in feel of the fabric makes it incredibly comfortable to wear, while the faded finish and distressed detailing add character and authenticity to the overall look. Stone washed denim can be dressed up or down, making it a versatile choice for both casual and formal occasions. Whether paired with a t-shirt and sneakers for a relaxed weekend look or dressed up with a blazer and boots for a night out, stone washed denim effortlessly bridges the gap between style and comfort.

Innovations in Stone Washing

While traditional stone washing methods remain popular, advancements in technology have led to innovations in the stone washing process. Eco-friendly alternatives, such as ozone wash and laser abrasion, have emerged as sustainable options that reduce water usage, chemical consumption, and energy consumption. These innovative techniques offer similar distressed effects to traditional stone washing while minimizing the environmental impact of denim production.

The Future of Stone Washing

As consumer demand for sustainable fashion continues to grow, the future of stone washing lies in eco-friendly alternatives and responsible manufacturing practices. By embracing sustainable techniques and materials, denim manufacturers can reduce their environmental footprint while meeting the demand for stylish and environmentally conscious denim garments. Stone washing will continue to be a staple in the denim industry, offering timeless style and unparalleled comfort for generations to come.

What are the main advantages of using stone washing in denim production?

Stone washing offers several advantages in denim production, including softening the fabric, achieving a worn-in look, and creating unique distressed effects. This technique adds character and authenticity to denim garments, making them more appealing to consumers.

How has the evolution of stone washing techniques impacted the denim industry?

The evolution of stone washing techniques has had a significant impact on the denim industry, allowing manufacturers to achieve a wide range of distressed effects and finishes. Innovations such as laser abrasion and ozone wash have emerged as sustainable alternatives to traditional stone washing methods, leading to more environmentally friendly denim production practices.

What role does stone washing play in shaping fashion trends and consumer preferences?

Stone washing has played a crucial role in shaping fashion trends and consumer preferences, particularly in the denim market. The distressed look achieved through stone washing has become synonymous with casual style and urban fashion, influencing the design of denim garments and accessories worldwide.

How do denim manufacturers ensure the quality and consistency of stone washed denim products?

Denim manufacturers employ stringent quality control measures to ensure the quality and consistency of stone washed denim products. This may involve testing different wash cycles, adjusting chemical concentrations, and monitoring production processes to achieve the desired effects. By adhering to strict quality standards, manufacturers can deliver high-quality stone washed denim products that meet consumer expectations.