In the realm of textile machinery, Tolkar stands as an industry leader, constantly innovating to meet the evolving needs of the textile finishing process. This article explores the groundbreaking Garment Finishing Machine by Tolkar, shedding light on its advanced features and the significant impact it has on the textile industry.

Tolkar’s Garment Finishing Machine: Elevating Textile Quality and Precision:

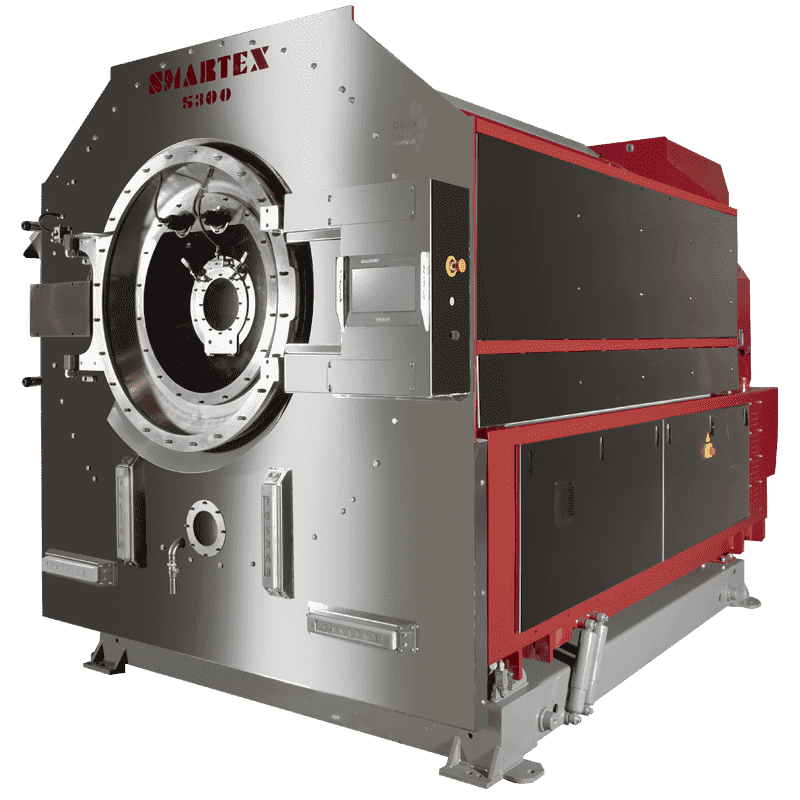

At the core of Tolkar’s commitment to excellence lies the Garment Finishing Machine, a technological marvel designed to revolutionize the textile finishing landscape. This machine seamlessly integrates precision, efficiency, and versatility to meet the diverse requirements of textile manufacturers.

Key Features of Tolkar’s Garment Finishing Machine:

- Versatile Finishing Capabilities: Tolkar’s Garment Finishing Machine is celebrated for its versatility, accommodating various garment types and materials. From delicate silks to robust denim, the machine ensures a consistent and flawless finishing touch, offering manufacturers unparalleled flexibility in their finishing processes.

- Precision Control for Impeccable Results: Equipped with cutting-edge control systems, the Garment Finishing Machine enables manufacturers to achieve unparalleled precision in finishing. From steam settings to pressure adjustments, every aspect is meticulously controlled, ensuring each garment receives a flawless finish, meeting the highest quality standards.

- Efficient Resource Utilization: Tolkar prioritizes resource efficiency, integrating technologies that minimize water and energy consumption during the finishing process. By implementing eco-friendly practices, the Garment Finishing Machine not only enhances operational efficiency but also aligns with Tolkar’s commitment to sustainable textile solutions.

Tolkar: A Legacy of Innovation in Textile Technology:

With a history steeped in textile innovation, Tolkar has consistently been a trailblazer in the industry. The Garment Finishing Machine stands as a testament to Tolkar’s dedication to pushing the boundaries of what is achievable in textile manufacturing.

Global Influence and Industry Trust:

Tolkar’s influence extends globally, with the Garment Finishing Machine becoming a symbol of reliability and efficiency in the textile sector. The seamless integration of technology and precision has solidified Tolkar’s position as a trusted partner for manufacturers worldwide.

Tolkar’s Garment Finishing Machine is not just a piece of equipment; it’s a game-changer in the textile finishing process. As industries seek more efficient, precise, and sustainable solutions, Tolkar continues to lead the way, shaping the future of garment finishing. Step into a new era of textile innovation with Tolkar – where every garment gets the finishing touch it deserves.

Tolkar’s Garment Finishing Machine is recognized for its versatile capabilities. How does the machine accommodate various garment types and materials, and what advantages does this versatility bring to manufacturers in terms of production flexibility?

Tolkar‘s Garment Finishing Machine accommodates various garment types and materials through its adaptable design and advanced technology. The machine is equipped with settings that can be adjusted based on the specific requirements of different fabrics, ensuring a consistent and flawless finish. This versatility provides manufacturers with the flexibility to efficiently process a wide range of garments, meeting diverse production demands.

Precision control is emphasized as a key feature of Tolkar’s Garment Finishing Machine. How does the machine achieve precision in finishing, and what role does precise control play in ensuring impeccable results for each garment?

Tolkar’s Garment Finishing Machine achieves precision through advanced control systems that regulate variables such as steam settings and pressure adjustments. This meticulous control ensures that each garment undergoes the finishing process with accuracy and consistency. Precise control is crucial in achieving impeccable results, meeting the highest quality standards in garment finishing for manufacturers.

Tolkar places a strong emphasis on resource efficiency in its Garment Finishing Machine. Could you elaborate on the technologies integrated into the machine that contribute to minimizing water and energy consumption, and how does this align with Tolkar’s commitment to sustainability?

Tolkar’s Garment Finishing Machine integrates technologies such as energy-efficient heating mechanisms and optimized steam usage to minimize water and energy consumption during the finishing process. This commitment aligns with Tolkar’s sustainable practices, offering manufacturers an eco-friendly solution that reduces the environmental impact of garment finishing while enhancing operational efficiency.

Tolkar is renowned for its legacy of innovation. How does the Garment Finishing Machine exemplify Tolkar’s dedication to pushing the boundaries of technology, and what advancements in garment finishing does it introduce to the textile manufacturing landscape?

Tolkar’s Garment Finishing Machine exemplifies the company’s dedication to innovation by introducing advanced features that redefine efficiency and precision in garment finishing. The machine represents a significant advancement in textile manufacturing by providing manufacturers with a state-of-the-art solution that ensures consistent, high-quality results. Its contribution to setting new standards in garment finishing solidifies Tolkar’s position as an industry leader at the forefront of technological innovation.